3D Printing and Kink

With 3D printing becoming widely available to the masses I’ve been seeing a concerning trend. 3D printed items made for use as sex or kink toys. Why is this concerning? There are plenty of awesome ways to use 3D printing for sex and kink but there are also very bad ways to use it. By bad, I mean a danger to your health that you may not be aware of if you’re not familiar with 3D printing and how it works.

Here are some very basic things about 3D printing that can affect your choices.

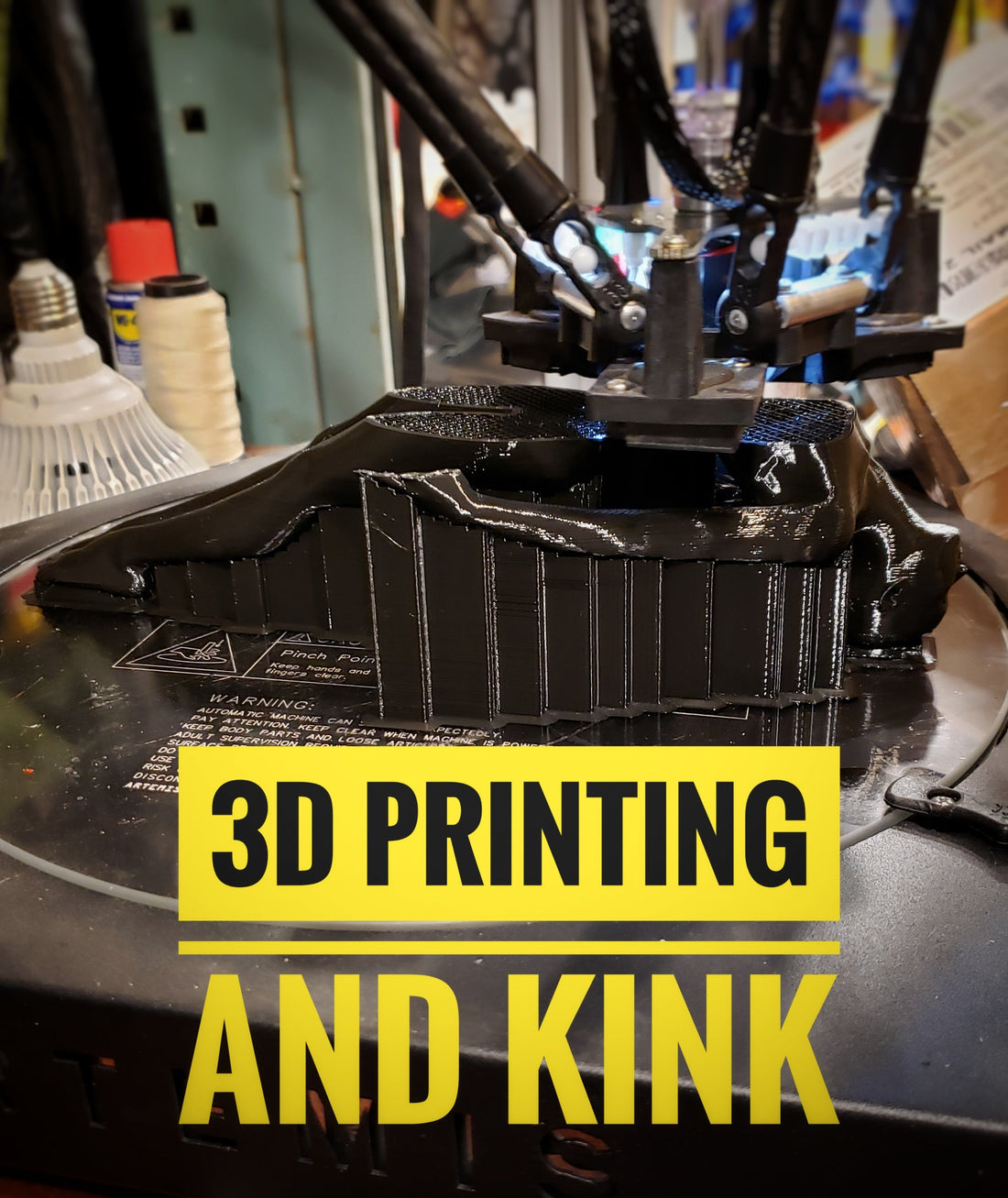

FDM Printing

There are two types of printers widely used by hobbyists and prosumers. FDM and resin printers. FDM (Fused Deposition Modeling) printers take in filament, picture the longest strand of spaghetti you’ve ever seen wrapped around a spool, and melts it and then lays it down on a printer bed layer by layer to create an object.

This type of printing is very popular since many inexpensive machines are available and filaments come in a wide array of colors.

Toys made with FDM printers are not suitable for toys meant to be insertables! The reason why is because when these printers make an object the layers create tiny unseeable havens for bacteria. These plastics melt at temps between 190 and 250c so they can’t be cleaned in something like a dishwasher for fear of melting them. Depending on the skill of the maker, they may or may not be watertight and fluids can get inside them making another home for bacteria.

Image from Matterhackers

Putting a condom on these toys does NOT solve this problem. Those same layer lines will rub at a condom and create micro-tears. These layers can also do the same thing to delicate anal and vaginal tissues.

While the types of filaments most commonly used in FDM printing are considered food/contact safe, like PLA and PETG, it is the manner used in their construction that makes them unsuitable for insertables. Some people like to try smoothing prints with acrylics, polymers, etc but I would argue that just because something looks smooth, doesn’t mean it is smooth at a microscopic level. You would also need to consider if the coating is contact safe or not. Most of the coatings I have seen people add, like acrylic or polyurethane are toxic when in contact with internal bits.

What about toys that aren’t insertables like wacky things, or pinchy things, or spikey things?

Go for it. It is plastic. Treat it like you would other plastic toys. If you bleed on it, make sure to clean it thoroughly. Anywhere your fluids can get, water and soap can also get. Most FDM prints are semi-hollow inside. They use what is called infill to create a grid (or other shape) inside the print to give it strength and structure, but it is essentially filled with thin plastic scaffolding that just creates a bunch of cavities and holes inside the print. A good print will be water tight, but this will depend on the skill of the maker.

*Note- Filament for 3D printers is entirely unregulated. There is no one overseeing what additives are put into filaments either to obtain colors or sheens or just to add fluffer material. Many filaments are made overseas, some from reliable and upstanding companies, and some from more shady origins.

Resin Printers

These printers work by using UV light to cure UV resin very slowly. It also does this layer by layer but this technique does not leave layer lines like FDM.

There are resins out there that are rated body and contact safe. They have even been used by the medical and dental industry for a long time. Unfortunately, these resins are not marketed to hobbyists and many are rather difficult to procure for the average person.

While resins used for medical purposes are regulated, resins for prosumer 3D printing are not. Each company has its own cocktail of UV resin and each one would have to be considered on its own to determine its safety for insertables.

The other concern with toys made this way is that once they have cured in the printer they usually require a wash or bath of isopropyl alcohol to remove excess resin and finish curing the print. Not all makers do this because its messy, time consuming, and the wash stations available on the market are expensive. Uncured resin is toxic!. If you touch a resin printed item and it feels sticky or tacky (and it’s not because of some nasty thing you just did) then do not use it and throw it away.

Have a resin printed toy that is fully cured and you’re willing to bet that the resin used is body-safe? Then maybe you’re comfortable using it for insertable purposes. I personally would recommend covering it with a condom or barrier just because we can’t guarantee the resin is as inert as silicone.

A cured resin print should be fine for non-insertable toys. They’re a bit easier to clean than FDM prints as they can be printed entirely solid or they are printed hollow but have a small hole somewhere so that the excess uncured resin could drain out. This means you could also drain out any fluids that got inside it.

But I need my insertables, damn it!

I feel you.

3D printing can be super useful for making insertables. You can print a mold of something that you then cast in silicone, or you can make a silicone mold of a 3D print and make a silicone cast from that.

All silicones are not created equal. For a silicone to be considered medical grade it must comply with U.S. 21 CFR 177.2600 and there are certain production standards that must be upheld during the making process. However, most silicone toys are not medical grade silicone and do not comply with FDA standards during production, but since they are being used only for a relatively short time the risk from them is extremely low.

I would recommend using platinum cure silicone over tin cure silicone. Tin cure is less expensive, but it does begin to lose integrity faster.

The Pros!

3D printing can be great for making toys that stay outside the body. I make paddles, floggers, and other toys that incorporate 3D printed pieces and they’re just as “safe” as other plastic toys. It also gives makers a whole new dimension to their creativity. We can easily customize products made specifically for us and our communities needs rather than just having to make do with things that already exist in the world.

PLA, a very popular type of filament for FDM printers, is a plant-based plastic that also decomposes within 45-90 days in the right conditions. For those trying to be more environmentally aware this is a huge upside.

*Additional note!

What about the strength of a 3D print for an impact play toy? Is it strong enough to be a "safe" toy?

First, lets stop with the hand wringing. Toys break all the time. It doesn't mean it shatters into a million pieces of shrapnel that lodge themselves into the players causing mass carnage. Let's keep discussions of safety in good faith under the presumption they are being used by adults with a modicum of sense.

The strength of a 3d printed item depends entirely on its design and the skill of the maker. Ive run over my paddles with my car, hit them repeatedly on my granite worktable with all my strength, and thrown them at pesky critters. No problems.

The settings of a "slice" file for a print have thousands of options and each one can change the integrity of the print dramatically. These settings are at the discretion of the maker. The idea that 3D printing is just turning on a machine and hitting go is false. A good amount of skill goes into 3D printing well. Just like a wooden paddle made by someone who knows nothing about woodworking might break, have splinters, or crack, a 3D print is the same way.

I test my prints myself by whacking them against a granite slab with more force than anyone would reasonably use on a human being with good intentions. So far so good. I don't believe in doing silly click bait strength tests like running it over with my car or pull meters because those conditions aren't applicable to the use.